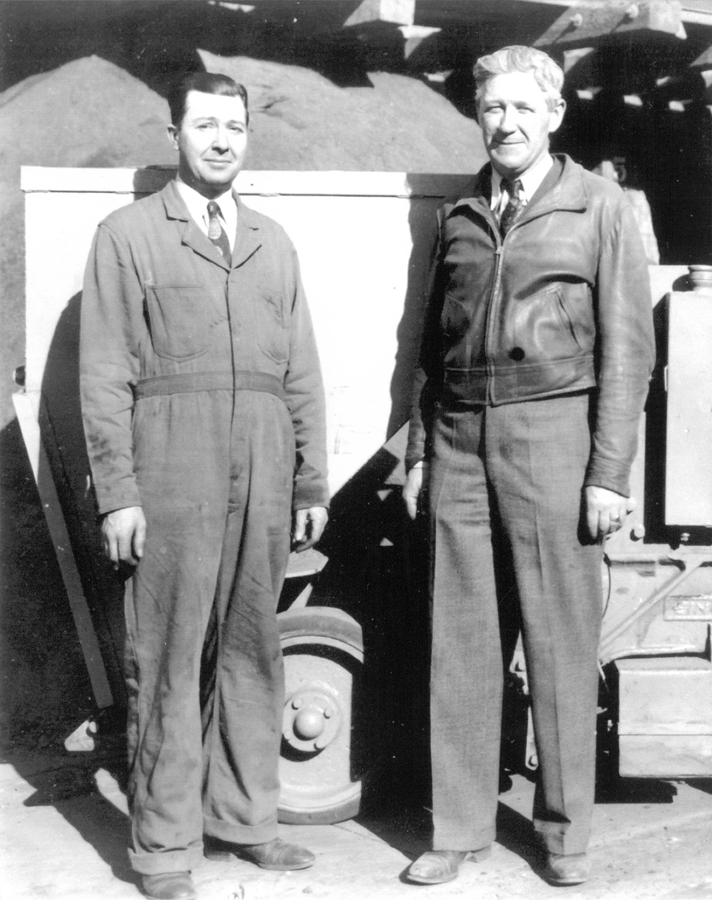

Anyone who has worked underground owes a debt of gratitude to Burt Royle, the principal inventor of the mucking machine, which greatly eased the job of removing the broken muck by hand shoveling to operating a powered machine, doing the job in less time and with much less exertion and back strain. Many unsuccessful attempts had been made to improve the mucking cycle, but the revolutionary design conceived by Burt Royle, with improvements by John Spence Finlay made possible the removal of muck faster and easier than ever thought possible.

Royle's idea for the mucking machine came partly from observing the arc motion of the shovel while mucking out a round of muck at the Lilly Mine in Eureka, Utah. His design permitted a small cross-section drift to be driven, similar to the drifts driven where hand mucking was used, and significantly smaller than those employing the mechanical devices then available.

John Spence (Jack) Finlay was born in Canada and immigrated in 1890. He worked for Anaconda in Butte, Montana and was sent down to Eureka to manage their North Lily mine. The depression was starting and Anaconda wanted a likely gold deposit explored. Funds to accomplish this were meager, so when Burt Royle approached him with plans for the overshot mucker, Finlay encouraged him, as he realized that the savings this machine could make in labor, time and powder could make possible exploration of the target.

In the old days, the mine superintendent wielded a lot of power. Finlay authorized the building of Royle's machine in the mine's shop. Since it was built largely out of parts from the mine's "bone yard" (scrap pile - supposedly including parts from a wrecked Model T Ford), costs were minimal. The machine was successful, where the October 15, 1931 issue of the Eureka Reporter stated that the mechanical mucker had been in use for 10 days without any breakdowns at the Big Hill Mine in Eureka, and could fill an "ordinary" mine car in one minute and twenty seconds.

An agreement was reached with a small Salt Lake foundry (Eastern Iron & Metals Co. (EIMCO)) for the manufacture of the machine. This invention was largely responsible for EIMCO's growth and success. Finlay retired and Royle became a full time consultant for EIMCO. In the course of his life, he received 17 patents, eight of which were for mining applications. Two of these patents were shared with Finlay.

Jack Finlay was inducted into the American Mining Hall of Fame as an Honoree from Mining's Past on 7 December 2013 in Tucson.

Bio courtesy of the Mining Foundation of the Southwest

~~~~~~~~~~~

Son of Spence Finlay and Alice Rankin. He was survived by his wife, Kathleen E.

Anyone who has worked underground owes a debt of gratitude to Burt Royle, the principal inventor of the mucking machine, which greatly eased the job of removing the broken muck by hand shoveling to operating a powered machine, doing the job in less time and with much less exertion and back strain. Many unsuccessful attempts had been made to improve the mucking cycle, but the revolutionary design conceived by Burt Royle, with improvements by John Spence Finlay made possible the removal of muck faster and easier than ever thought possible.

Royle's idea for the mucking machine came partly from observing the arc motion of the shovel while mucking out a round of muck at the Lilly Mine in Eureka, Utah. His design permitted a small cross-section drift to be driven, similar to the drifts driven where hand mucking was used, and significantly smaller than those employing the mechanical devices then available.

John Spence (Jack) Finlay was born in Canada and immigrated in 1890. He worked for Anaconda in Butte, Montana and was sent down to Eureka to manage their North Lily mine. The depression was starting and Anaconda wanted a likely gold deposit explored. Funds to accomplish this were meager, so when Burt Royle approached him with plans for the overshot mucker, Finlay encouraged him, as he realized that the savings this machine could make in labor, time and powder could make possible exploration of the target.

In the old days, the mine superintendent wielded a lot of power. Finlay authorized the building of Royle's machine in the mine's shop. Since it was built largely out of parts from the mine's "bone yard" (scrap pile - supposedly including parts from a wrecked Model T Ford), costs were minimal. The machine was successful, where the October 15, 1931 issue of the Eureka Reporter stated that the mechanical mucker had been in use for 10 days without any breakdowns at the Big Hill Mine in Eureka, and could fill an "ordinary" mine car in one minute and twenty seconds.

An agreement was reached with a small Salt Lake foundry (Eastern Iron & Metals Co. (EIMCO)) for the manufacture of the machine. This invention was largely responsible for EIMCO's growth and success. Finlay retired and Royle became a full time consultant for EIMCO. In the course of his life, he received 17 patents, eight of which were for mining applications. Two of these patents were shared with Finlay.

Jack Finlay was inducted into the American Mining Hall of Fame as an Honoree from Mining's Past on 7 December 2013 in Tucson.

Bio courtesy of the Mining Foundation of the Southwest

~~~~~~~~~~~

Son of Spence Finlay and Alice Rankin. He was survived by his wife, Kathleen E.

Sponsored by Ancestry

Advertisement

Explore more

Sponsored by Ancestry

Advertisement